泊头市鑫程机械有限公司生产各种弧形齿鼓形齿联轴器,直齿型齿式联轴器。我公司拥有10余台数控插齿机,数控滚齿机,模数从1模到16模,工件直径从20mm到1.2米,可满足联轴器行业各种齿的要求,本公司有的技术工程师可以测量,计算和设计,可来图来样定制GIICLZ齿轮联轴器,铸钢件,锻件,42CRMO材质,45#钢圆钢材质的都可以。

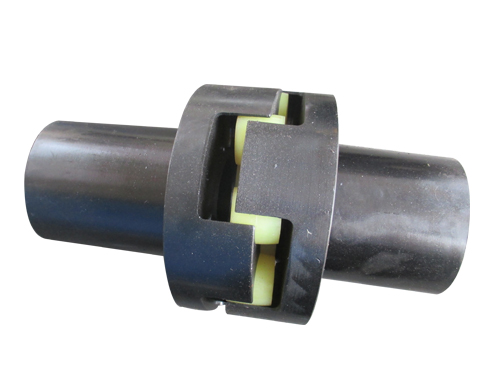

GⅡCLZ型接中间轴窄型鼓形齿式联轴器齿间距小,允许相对径向位移小,结构紧凑,转动惯量小,适用于公称转矩400-450000n.m联接水平两同轴线轴系运动。是由齿数相同的内齿圈和带外齿的凸缘半联轴器等零件组成。外齿分为直齿和鼓形齿两种齿形,所谓鼓形齿即为将外齿制成球面,球面中心在齿轮轴线上,齿侧间隙较一般齿轮大,鼓形齿联轴器可允许较大的角位移(相对于直齿联轴器),可齿的接触条件,提高传递转矩的能力,延长使用寿命。有角位移时沿齿宽的接触状态。

齿式联轴器在工作时,两轴产生相对角位移,内外齿的齿面周期性作轴向相对滑动,必然形成齿面磨损和功率消耗,因此,齿式联轴器需在有良好和密封的状态下工作。齿式联轴器径向尺寸小,承载能力大,常用于低速重载工况条件的轴系传动,并经动平衡的齿式联轴器可用于高速传动,如燃汽轮机的轴系传动。由于鼓形齿式联轴器角向补偿大于直齿式联轴器,均广泛采用鼓形齿式联轴器。

目前鼓形齿联轴器被越来越多地投入应用,在生产实践占有重要地位鼓形齿联轴器适用场合多为重载、且两联接轴可以调整误差及摆角的机械传动中cl标准系列的鼓形齿联轴器正广泛应用,机械传动鼓形齿联轴器作为连接动力传输的关键基础部件

我公司也承接非标准联轴器的制造,欢迎您的咨询、选购。

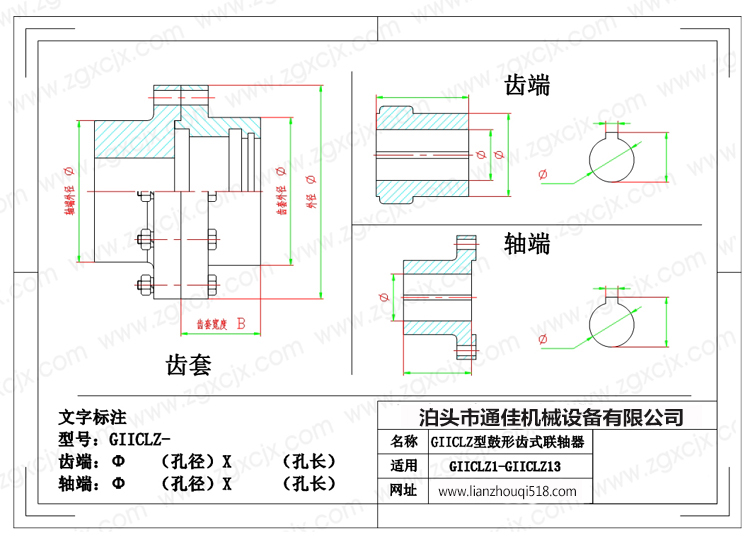

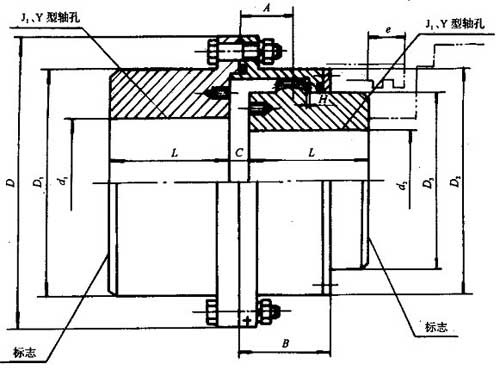

GⅡCLZ型基本型(窄型)鼓形齿式联轴器基本参数和主要尺寸(JB/T 8854.3-2001)(单位:mm)

| 型号 | 公称扭矩/N.m | 许用转速 /r/min | 轴孔直径 d1 d2 | 轴孔长度L | D | D1 | D3 | C | 质量Kg | |

| Y | J1 | |||||||||

| GⅡCLZ1 | 400 | 4000 | 14,16,18,19 | 42 | - | 103 | 71 | 50 | 8 | 3.5 |

| 20,22,24 | 52 | 38 | 3.3 | |||||||

| 25,28 | 62 | 44 | 3.5 | |||||||

| 30,32,35,38* | 82 | 60 | 4.1 | |||||||

| 40*,42*,45*,48*,50* | 112 | 84 | 5.7 | |||||||

| GⅡCLZ2 | 710 | 4000 | 20,22,24 | 52 | - | 115 | 83 | 60 | 8 | 5.3 |

| 25,28 | 62 | 44 | 4.8 | |||||||

| 30,32,35,38 | 82 | 60 | 5.7 | |||||||

| 40,42,45,48*,50*,55*,56* | 112 | 84 | 7.2 | |||||||

| 60* | 142 | 107 | 9.2 | |||||||

| GⅡCLZ3 | 1120 | 4000 | 22,24 | 52 | - | 127 | 95 | 75 | 8 | 3.8 |

| 25,28 | 62 | 44 | 7.8 | |||||||

| 30,32,35,38 | 82 | 60 | 7.6 | |||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 9.8 | |||||||

| 60*,63*,65*,70* | 142 | 107 | 12.5 | |||||||

| GⅡCLZ4 | 1800 | 4000 | 38 | 82 | 60 | 149 | 116 | 90 | 8 | 10.5 |

| 40,42,45,48,50,55,56 | 112 | 84 | 13.5 | |||||||

| 60,63,65,70*,71*,75* | 142 | 107 | 16.5 | |||||||

| 80* | 172 | 132 | 19.4 | |||||||

| GⅡCLZ5 | 3150 | 4000 | 40,42,45,48,50,55,56 | 112 | 84 | 167 | 134 | 105 | 10 | 18.1 |

| 60,63,65,70,71,75 | 142 | 107 | 23.1 | |||||||

| 80*,85*,90* | 172 | 132 | 28.5 | |||||||

| GⅡCLZ6 | 5000 | 4000 | 45,48,50,55,56 | 112 | 84 | 187 | 153 | 125 | 10 | 23.9 |

| 60,63,65,70,71,75 | 142 | 107 | 29.3 | |||||||

| 80,85,90,95* | 172 | 132 | 35.4 | |||||||

| 100*,105* | 212 | 167 | 36.2 | |||||||

| GⅡCLZ7 | 7100 | 3750 | 45,48,50,55,56 | 112 | 84 | 204 | 170 | 140 | 10 | 29.6 |

| 60,63,65,70,71,75 | 142 | 107 | 36.3 | |||||||

| 80,85,90,95* | 172 | 132 | 43.8 | |||||||

| 100*,105* | 212 | 167 | 54.3 | |||||||

| GⅡCLZ8 | 10000 | 3300 | 50,55,56 | 112 | 84 | 230 | 186 | 155 | 12 | 37.8 |

| 60,63,65,70,71,75 | 142 | 107 | 46.1 | |||||||

| 80,85,90,95 | 172 | 132 | 54.9 | |||||||

| 100,105*,110* | 212 | 167 | 67.4 | |||||||

| GⅡCLZ9 | 16000 | 3000 | 60,63,65,70,71,75 | 142 | 107 | 256 | 212 | 180 | 60 | |

| 80,85,90,95 | 172 | 132 | 71.8 | |||||||

| 100,110,115,120,125 | 212 | 167 | 88 | |||||||

| 130,135,140*,150* | 252 | 202 | 104.4 | |||||||

| GⅡCLZ10 | 22400 | 2650 | 65,70,71,75 | 142 | 107 | 287 | 239 | 200 | 14 | 76.1 |

| 80,85,90,95 | 172 | 132 | 91.1 | |||||||

| 100,110,120,125 | 212 | 167 | 111.5 | |||||||

| 130,140,150 | 252 | 202 | 133.5 | |||||||

| GⅡCLZ11 | 35500 | 2350 | 110,120,125 | 212 | 167 | 325 | 250 | 235 | 137 | |

| 130,140,150 | 252 | 202 | 162.4 | |||||||

| 160,170,175 | 302 | 242 | 193 | |||||||

| GⅡCLZ12 | 50000 | 2100 | 130,140,150 | 252 | 202 | 362 | 286 | 270 | 212.8 | |

| 160,170,180 | 302 | 242 | 268 | |||||||

| 190,200 | 352 | 282 | 290 | |||||||

| GⅡCLZ13 | 71000 | 1850 | 150 | 252 | 202 | 412 | 322 | 300 | 18 | 272.3 |

| 160,170,180,185 | 302 | 242 | 320 | |||||||

| 190,200,220,225 | 352 | 282 | 370 | |||||||

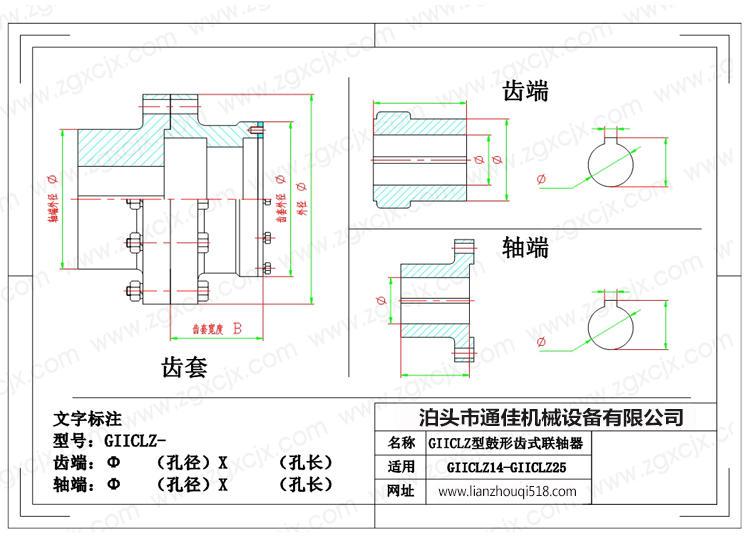

| GⅡCLZ14 | 112000 | 1650 | 170,180,185 | 302 | 242 | 462 | 420 | - | 22 | 389 |

| 190,200,220 | 352 | 282 | 438 | |||||||

| 240,250 | 410 | 330 | 509 | |||||||

| GⅡCLZ15 | 180000 | 1500 | 190,200,220 | 352 | 282 | 512 | 465 | - | 22 | 566 |

| 240,250,260 | 410 | 330 | 650 | |||||||

| 280,285 | 470 | 380 | 740 | |||||||

| GⅡCLZ16 | 250000 | 1300 | 220 | 352 | 282 | 580 | 522 | - | 28 | 751 |

| 240,250,260 | 410 | 330 | 857 | |||||||

| 280,300,320 | 470 | 380 | 974 | |||||||

| GⅡCLZ17 | 355000 | 1200 | 250,260 | 410 | 330 | 644 | 582 | - | 28 | 1110 |

| 280,290,300,320 | 470 | 380 | 1255 | |||||||

| 340,360,365 | 550 | 450 | 1465 | |||||||

| GⅡCLZ18 | 500000 | 1050 | 280,295,300,320 | 470 | 380 | 726 | 658 | - | 28 | 1580 |

| 340,360,380 | 550 | 450 | 1830 | |||||||

| 400 | 650 | 540 | 2160 | |||||||

| GⅡCLZ19 | 710000 | 950 | 300,320 | 470 | 380 | 818 | 748 | - | 32 | 2115 |

| 340,350,360,380,390 | 550 | 450 | 2457 | |||||||

| 400,420,440,450,460,000 | 650 | 540 | 2892 | |||||||

| GⅡCLZ20 | 1000000 | 800 | 360,380,390 | 550 | 450 | 928 | 838 | - | 32 | 3223 |

| 400,420,440,450,460,000,000 | 650 | 540 | 3793 | |||||||

| 530,540 | 800 | 680 | 4680 | |||||||

| GⅡCLZ21 | 1400000 | 750 | 400,420,440,450,460,000,000 | 650 | 540 | 1022 | 928 | - | 40 | 4780 |

| 530,560,600 | 800 | 680 | 5905 | |||||||

| GⅡCLZ22 | 1800000 | 650 | 450,460,480,500 | 650 | 540 | 1134 | 1036 | - | 40 | 6069 |

| 530,560,600,630 | 800 | 680 | 7504 | |||||||

| 670,680 | 900 | 780 | ||||||||

| GⅡCLZ23 | 2500000 | 600 | 500,530,560,600,680 | 800 | 680 | 1282 | 1178 | - | 50 | 9633 |

| 670,700,710,760,770 | 900 | 780 | 11133 | |||||||

| GⅡCLZ24 | 3550000 | 550 | 560,600,630 | 800 | 680 | 1428 | 1322 | - | 50 | 12460 |

| 670,700,710,750,800 | 900 | 780 | 14465 | |||||||

| 850,880 | 1000 | 880 | 16110 | |||||||

| GⅡCLZ25 | 4500000 | 460 | 670,700,710,750 | 900 | 780 | 1644 | 1538 | - | 50 | 19837 |

| 800,850 | 1000 | 880 | 22381 | |||||||

| 900,950 | - | 980 | 24765 | |||||||

| 10,001,040 | - | 1100 | 27797 | |||||||

注:表中带"*"的轴孔尺寸只适用于d1选用。